INDRA

HOME / INDRA

ORIGIN

Indra is of ancient but unclear origin. Aspects of Indra as a deity are cognate to other Indo-European gods; they are either thunder gods such as Thor, Perun, and Zeus who share parts of his heroic mythologies, act as king of goas, and all are linked to "rain and thunder".

Indra inspired our designers, as the King of the Gods and God of the Thunder, fast as lightning, everything that we had in mind to make the truck strong, fast, and light, also we use the "gods material" Titanium as standard.

ABOUT US

Since 2013, ALSENTRUCKS has been focused on building the highest quality, best-performing parts for today's sport longboard skate.

That's why we only use the highest grade materials available in the market and the most precision CNC Machines, also the best quality control, with the world's most Advanced Mathematical Tools in Metrology.

Products are designed using the latest computer software, with Aerodynamics Flow Analysis and Finite Element Analysis, each product is then subjected to rigorous Laboratory tests, also rigorous tested by our Worldwide ambassador team in the countries: USA, Mexico, Colombia, Brazil, France, Australia, China & Philippines tests and approves the performance, also IDF Worldwide circuit Race track testing to ensure proper performance in the most extreme conditions.

CNC MACHINERY WORKSHOP

ALSENTRUCKS offers you longstanding experience in technical and complex manufacturing, we count on the most advanced machine setup, from the brand Haas.

The largest manufacturer of machine tools in the Western world, Haas is consistently considered the gold standard when it comes to CNC machines. Gene Haas founded Haas Automation, Inc., in 1983 to manufacture economical and reliable machine tools. The company entered the machine tool industry with the first-ever, fully automatic, programmable collet indexer - a device used to position parts for machining with very high accuracy.

QUALITY CONTROL

All trucks are fully inspected after final machining and before the anodizing process. We utilize a Computerized Statistical Process Control (that will be annexed at the serial number of each part) to carefully monitor each of the crucial process stages to ensure consistency, accuracy, and integrity of the components. We take great pride in our accomplishments and build on them every day to ensure customer satisfaction.

We capture measurements three-dimensionally with the Mitutoyo CRYSTA-Apex Sand Apex C, crafted using a joystick controller. These models have a temperature correction function from 16 to 26 degrees Celsius so as to produce precision measurements on the shop floor. These measuring instruments are made of lightweight materials and implemented with high-tech machinery to ensure high accuracy and motion stability while also enjoying affordability. Aside from the point-to-point measurement, the Metris laser probe and MPP-3100 are useful for scanning contact and non-contact scanning.

INDRA GEOMETRY PART ONE

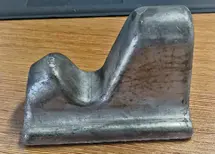

INDRA pivot is longer than the earlier model and also has a "flange" in its base to increase the hanger alignment to the baseplate, generating a lot more stability and also grip to your feet, Alsentrucks use the Riptide pivot cup as a standard big pivot cup delivery a very smooth feel to the rider by absorbing all the pavement vibrations during the ride check the two images around.

ULTRA LEAN BUSHING SEAT

The Precision Truck Alsen INDRA is developed to have majestic lean, the bushing seat has a 3D concave to allow the bushing to have a better deformation, which consists of a side lateral degree chamfer in the bushing seat, the kingpin bypass hole has a huge space in the horizontal to permit the hanger movement don't have any bite in the kingpin also in the vertical to don't have problems when assembly seat, check image at the right shows how the bushing seat skirt around the bushing perfectly.

INDRA GEOMETRY PART TWO

The INDRA Hanger is Designed for high-speed races, with very closed corners, it is 136mm wide, with the axles 9mm on each side turning into a 154mm Hanger, plus the axle spacers let your Hanger with the option to use 164mm IMAGE 3A

*images merely illustrative

The precision truck INDRA is designed to have a very smooth and great turn in the closed corner and, also in the same time have a lot of stability at high speeds, the design has one feature called RAKE to increase the maneuverability.

"Rake" is the terminology used to describe a geometry equation, which means a value measured in millimeters, Rake consists of the distance offset of the axles compared to the pivot on the positive side acts like a lever in the hanger providing a lot more force from your feet by the hanger to deform the bushing, plus, the rake can be Positive or Negative, depends on how you assembly your hanger in the base-plate. Positive rake mount, you have a lot more force to turn, good for circuits and freestyle riding.

Negative rake mount, you have less force to turn. so have more stability at high speeds also less turn. Bellow has some info-graphics showing the difference between Rakeless, Positive Rake, and Negative Rake.

A - Positive Rake Trajectorie

B - Rakeless Irajectorie

C - Negative Rake

INDRA NANO SERIES

In the past, you needed a big board to get stability. Now (last couple of years) quality of board construction and trucks/wheels improved a lot. So you can run narrow/short boards with tight trucks.

Brief history:

In the mid of the year 2000, Downhill Professional Skate began to appear the first precision trucks, people wondered if wider hanger trucks were more stable than smaller ones because the first trucks ever were from roller skates, they were very small, turned fast, but unstable at high speeds, after it when one of the first precision truck appears, it was 204mm wide, they really were more stable, but, with decades of skating, with the improving of wheels technology, people were slowly noticing that also steer a wide truck like this is very difficult, also wider hangers provide less grip than the smaller ones, Alsen Trucks understand time by a cycle, not a straight line, things that were good back then have the potential to resurge from the ashes.

The push for Trucks that could make tight curves between 2010-2016 took a while and people were focusing on getting the most amount of grip from their wheels, now that wheel tech is the best ever and most DH wheels grip insanely more and roll faster.

Now trucks are getting tweaked, basically squeezing the most out of the lemon trying to get more grip/turn/lean, and with trucks geometry getting more advanced stability is easy to overcome now.

Mix up the benefits such as (Tall Bushing, Axle Height, Rake, 3D Bushing Seat, Forged Structure, CNC Machined surface. Improved Flanged Pivot, Big Riptide pivot cup), delivery improved steering, tons of grip and stability.

INDRA project at the time had an internal codename PL2, passed for hundreds of formats and geometries exhausting testing in the IDF world circuit before the final form was released, the project started in 2016, and it took 3 years of development and testing to release in 2019.

We are proud to present you the INDRA Nano Series.

WIDTH: 96 MILLIMETERS

WEIGHT: 100 GRAMS

WIDTH: 116 MILLIMETERS

WEIGHT: 113 GRAMS

WIDTH: 126 MILLIMETERS

WEIGHT: 117 GRAMS

WIDTH: 136 MILLIMETERS

WEIGHT: 121 GRAMS

BASEPLATES

Alsen Trucks have tall bushing baseplates to enjoy the maximum lean possible, material is forged before the machine providing very strong baseplates to you, you can choose what's the best baseplate for your skate style, 25º has the minimum turn, and progressively the turn increase with the angle passing for 30º 45º 48º, for race most riders like use greater angle in front and smaller in the rear, like 48/25º or 45/30º, you can find more about the riders taste in our AlsenTrucks International Group.

FORGING

Forging is one of the oldest known metalworking processes.

Traditionally, forging was performed by a smith using a hammer and anvil, though introducing water power to the production and working of iron in the 12th century allowed the use of large trip hammers or power hammers that exponentially increased the amount and size of iron that could be produced and forged easily.

The smithy or forge has evolved over centuries to become a facility with engined processes, production equipment, tooling, raw materials, and products to meet the demands of modern industry. Forging can produce a piece that is stronger than an equivalent cast or machined part.

As the metal is shaped during the forging process, its internal grain texture deforms to follow the general shape of the part. As a result, the texture variation is continuous throughout the part, giving rise to a piece with improved strength characteristics. Additionally, forgings can achieve a lower total cost than casting or fabrication. Considering all the costs that are incurred in a product’s life cycle from procurement to lead time to rework, and factoring in the costs of scrap, downtime, and other quality considerations, the long-term benefits of forgings can outweigh the short-term cost savings that castings or fabrications might offer.

Alsen Trucks developed a special tool to Forge the material before machining to enjoy all the benefits shown, this way of production Forge then CNC, is that made the most strong and precise aluminium parts ever. Aero-Espacial grade pieces of technology.

FINITE ELEMENT ANALYSIS

It's essential in the design of a great Precision Truck that weight is kept to a minimum, but strength and performance are optimized. for both strength and weight. In essence, the new INDRA design concept was purely a byproduct of the strength and functional requirements of the part. Even design details such as the 'Xs' were driven entirely by engineering analysis and not arbitrary design decisions. Using the results as our guideline, we then designed and modeled a part that was manufacturable using CNC machines.

Introduction to Finite Element Analisys

The finite element method (FEM) is a numerical method for solving problems in engineering and mathematical physics. It is also referred to as finite element analysis (FEA). Typical problem areas of interest include structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The analytical solution of these problems generally requires the solution to boundary value problems for partial differential equations. The finite element method formulation of the problem results in a system of algebraic equations.

The method yields approximate values of the unknowns at the discrete number of points over the domain. To solve the problem, it subdivides a large problem into smaller, simpler parts that are called finite elements. The simple equations that model these finite elements are then assembled into a larger system of equations that models the entire problem. FEM then uses variational methods from the calculus of variations to approximate a solution by minimizing an associated error function.

Discretization

Depending on the author, the word "element" in the "finite element method" refers either to the triangles in the domain, the piecewise linear basis function, or both. So for instance, an author interested in curved domains might replace the triangles with curved primitives, and so might describe the elements as being curvilinear.

On the other hand, some authors replace "piecewise linear" with "piecewise quadratic" or even "piecewise polynomial". The author might then say "higher order element" instead of "higher degree polynomial". The finite element method is not restricted to triangles or tetrahedra in 3-D, or higher order simplexes in multidimensional spaces), but can be defined on quadrilateral subdomains (hexahedra, prisms, or pyramids in 3-D, and so on). Higher-order shapes (curvilinear elements) can be defined with polynomial and even non-polynomial shapes (e.a. ellipse or circle).

MATERIALS PARALLEL

The most common materials used in Precision Trucks, are KingPin and Axles, Steel 4130, and Stainless Steel 304, rarely used are the supreme Titanium GRS Ti-6A -4V. The hangers and Baseplates are 6061-T6 or 7075-T6.

Sounds interesting isn't it? But, how can we know how strong are each of these materials? Below a brief explanation of how we measure the strength of the materials.

Ultimate Tensile Strength is the capacity of a material or structure to withstand loads tending to elongate, as opposed to compressive strength, which withstands loads tending to reduce size. In other words, tensile strength resists tension (being pulled apart), whereas compressive strength resists compression (being pushed together).

Ultimate tensile strength is measured by the maximum stress that a material can withstand while being stretched or pulled before breaking. In the study of the strength of materials, tensile strength, compressive strength, and shear strength can be analyzed independently. Tensile strength is defined as stress, which is measured as force per unit area. For some non-homogeneous materials. A United States customary unit is pounds per square inch Ilb

Next we have a table with the UTS into about each

Fatigue Strength is an expression used to describe a property of materials: the amplitude for a range of cyclic stress that can be applied to the material without causing fatigue failure. Ferrous alloys and titanium alloys have a distinct limit, an amplitude below which there appears to be no number of cycles that will cause failure.

Tensile Yield Strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins. Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is The material setup standard used by ALSENTRUCKS for Hanger and Baseplate is Aluminum 7075-T6, 183,000psi) UIS, compared to 6061-T6 145,000psil UTS It's 184.44% stronger, for Kingpin and Axle setup used is Titanium GR5 ( 170,000ps) UTS, compared to Steel 4130 (97,200) UTS is 174,89% stronger also 168.79% lighter. You can ride in the rain without any worry, titanium is immune to corrosion, plus you have the option of anodizing in many different colors. The fatigue strength of titanium is 102,000psi, 10,000,000 Cycles unnotched, simplifying means you can change the wheels 10 million times without damaging the axles, and you will not have any problems with smashed threads.

Because titanium alloys have a high tensile strength-to-density ratio, high corrosion resistance, fatigue resistance, high crack resistance, and the ability to withstand moderately high temperatures without creeping, they are used in aircraft, armor plating, naval ships, spacecraft, and missiles. For these applications, titanium is alloyed with aluminum, zirconium, nickel, vanadium, and other elements to manufacture a variety of components including critical structural parts, fire walls, landing gear, exhaust ducts (helicopters), and hydraulic systems. In fact, about two-thirds of all titanium metal produced is used in aircraft engines and frames.

The SR-71 "Blackbird" was one of the first aircraft frames where titanium was used, paving the way for much wider use in modern military and commercial aircraft. An estimated 59 metric tons (130,000 pounds) are used in the Boeing 777, 45 in the Boeing 747, 18 in the Boeing 737, 32 in the Airbus A340, 18 in the Airbus A330, and 12 in the Airbus A320. The Airbus A380 may use 77 metric tons, including about 11 tons in the engines. In engine applications, titanium is used for rotors, compressor blades, hydraulic system components, and nacelles. The titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

AERODYNAMICS AND WEIGHT EFFICIENCY ANALYSIS

All the truck design is thought to optimize the strength and lightness of the trucks, the advanced rounded shape provides better aerodynamic and weight efficiency compared to squared shape trucks in the image at left shows the INDRA design inside a squared truck shape, repair the empty spaces in the fillets, most of precision trucks brands uses more simple squared shape because it's more easy to machine, take less hours to mill.

The rounded shape is 23% lighter than the squared one and also has 27% better drag efficiency.

ANODIZED COLORS PRESENTATION

We have available the following anodized colors options:

-

Black

-

Titanium Grey

-

Raw Polish

-

Blue Steel

-

Green Mint

-

Purple

-

Gold

-

Red Brick

TEAM RIDERS

JOSH EVANS

November 08, 2017

"These trucks are just plain incredible the turn you get from the dished bushing seat coupled with the rake adds a whole new level to truck leaning andrallying corners. This also allows for perfect return to centre every time.

The dished bushing seat along with the surface area of the pivot means that the alsens are extremely stable while maintaining. I've also found that because of the level of turn available you need to lean less giving you increased grip and snappier slides.

The light weight aluminium 7075- t6 helps keep your setup light which if you're walking up hills all day like I often am is a huge benefit. Add titanium gr5 axles in the mix and you have a lightweight. Strong truck with the ability for Multiple width options.

Overall alsen trucks have given me the confidence to push my limits in all forms of my skateboarding and I aam extremely stoked with how they have turned out."

KOREY KAMP

May 28, 2019

“I have been riding Alsen Indras for a year now and I have ridden them in just about every condition, over just about every pavement and over 110km/hr. Through all of this, these wonderful trucks have been able to take lines, grip hard and still be super stable like nothing else I’ve ridden. Indras offer a super open bushing seat that allows for more depth of turn out of the tall bushings while still being very stable at high speeds, this combo also dampens the effects of rough roads or flat spotted wheels, providing a nice smooth role. Indras come in just about any colour and configuration you could think of, so you can really personalise your setup!

Personally, I have had the privilege of skating both the 154-164 45/30 configuration and the 134-144 48/25 configuration. I was able to utilise both of these set ups stand up and hands down and so will you!”

OSCAR GUTIERREZ

June 27, 2017

"We've been working on this new trucks for the past year. This last design is our ath prototype and after all the changes and testing we are sure this is the best downhill skateboarding truck in the market. This new model turns so much that feels like a carving truck but with the stability that no other truck has. At first I thought they were too loose but as soon as you ride them you feel so comfortable and you can take lines that you never took before. Also they are super light and strong so you can do tricks without problems. I'm riding the 174mm right now and I'm sure they are the best trucks I have ever rode!"